Report the ad

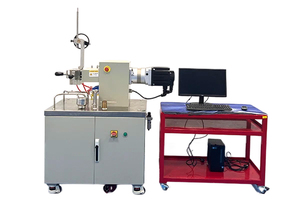

Torque Rheometer - Islamabad

Friday, 4 July 2025

Item details

City:

Islamabad

Offer type:

Sell

Item description

RTHI-06/02

The torque rheometer is an ideal device for studying the flow, plasticization, heat and shear stability of materials. The rheometer provides a dynamic measurement method that is closer to actual processing. It can continuously, accurately and reliably measure the rheological properties of materials under conditions similar to actual processing, such as the mixing of multi-component materials, cross-linking and curing of thermosetting resins, vulcanization of elastomers, dynamic stability of materials, and the influence of screw speed on system processing performance.

Non-contact dynamic torque sensor is used, with high data test accuracy and good repeatability

Building block structure design, the internal mixing chamber and rotor can be flexibly disassembled and assembled, and the material can be easily cleaned

The internal mixing chamber and rotor are made of high-performance corrosion-resistant and wear-resistant materials

High-performance servo motor, wide speed regulation range, more stable speed

Powerful and good human-computer interaction based on self-developed special software

High torque and temperature measurement accuracy, sensitive to subtle differences in formula

Humanized structure design, more convenient operation

Application range

Polymer material formula design

Raw material performance and quality inspection

PVC melting property test

Plasticizer absorption performance test of PVC dry blend

Thermal and shear stability test of thermoplastic materials

Formula design of sintering molding materials of inorganic powders such as metals and ceramics

POTOP Co., Ltd. was established in 2009 and is located in Panyu District, Guangzhou.

Scale: The company covers an area of 9,000 square meters and is a manufacturer of new polymer molding experimental equipment. Main business: manufacturing of polymer rheological properties characterization instruments, polymer processing and molding experimental equipment, and new functional film molding R&D experimental equipment. There are R&D, design, production, sales, process debugging, laboratories, after-sales and other departments, with 110 employees.

From August 2011 to date, 886 units (sets) of products have been sold and delivered, including 383 units (sets) of functional film equipment.

Dozens of major technological developments have been completed, with a total of 66 patents, and 5 national and group standards have been participated in the compilation.

Quality control: A complete ISO management system, passed ISO9001 quality management system certification.

Product and price advantages: core technology, independent research and development, product manufacturing, independent completion. Equipped with six sales teams, mainly based on direct sales strategies, shortening sales channels, and providing customers with more professional services. We provide customized services, actively interact, and the equipment will be shipped after it is debugged.

Our team's slogan is: 100% high satisfaction, turning plastic into gold

Guangzhou Putong adopts the business model of "product end + high-function film + customized service". Based on the product end, it transforms the experimental equipment at the experimental end into process trial equipment at the product end and the market end. The high-function films studied by the equipment are widely used in electromagnetics, optics, acoustics and other fields. It echoes the national industrial development direction of new materials, new energy and environmental protection.

Guangzhou Putong puts meeting customer needs first and is willing to be a 24-hour supplier to customers. When providing customers with customized experiments and test equipment, it will do a good job in technical docking and pre-sales experimental testing services. Guangzhou Putong has set up several on-site process departments to provide customers with pre-sales experimental testing services, delivery and adjustment services, customer on-site adjustment services and 48-hour response after-sales services to ensure the smooth progress of customers' scientific research work.

The torque rheometer is an ideal device for studying the flow, plasticization, heat and shear stability of materials. The rheometer provides a dynamic measurement method that is closer to actual processing. It can continuously, accurately and reliably measure the rheological properties of materials under conditions similar to actual processing, such as the mixing of multi-component materials, cross-linking and curing of thermosetting resins, vulcanization of elastomers, dynamic stability of materials, and the influence of screw speed on system processing performance.

Non-contact dynamic torque sensor is used, with high data test accuracy and good repeatability

Building block structure design, the internal mixing chamber and rotor can be flexibly disassembled and assembled, and the material can be easily cleaned

The internal mixing chamber and rotor are made of high-performance corrosion-resistant and wear-resistant materials

High-performance servo motor, wide speed regulation range, more stable speed

Powerful and good human-computer interaction based on self-developed special software

High torque and temperature measurement accuracy, sensitive to subtle differences in formula

Humanized structure design, more convenient operation

Application range

Polymer material formula design

Raw material performance and quality inspection

PVC melting property test

Plasticizer absorption performance test of PVC dry blend

Thermal and shear stability test of thermoplastic materials

Formula design of sintering molding materials of inorganic powders such as metals and ceramics

POTOP Co., Ltd. was established in 2009 and is located in Panyu District, Guangzhou.

Scale: The company covers an area of 9,000 square meters and is a manufacturer of new polymer molding experimental equipment. Main business: manufacturing of polymer rheological properties characterization instruments, polymer processing and molding experimental equipment, and new functional film molding R&D experimental equipment. There are R&D, design, production, sales, process debugging, laboratories, after-sales and other departments, with 110 employees.

From August 2011 to date, 886 units (sets) of products have been sold and delivered, including 383 units (sets) of functional film equipment.

Dozens of major technological developments have been completed, with a total of 66 patents, and 5 national and group standards have been participated in the compilation.

Quality control: A complete ISO management system, passed ISO9001 quality management system certification.

Product and price advantages: core technology, independent research and development, product manufacturing, independent completion. Equipped with six sales teams, mainly based on direct sales strategies, shortening sales channels, and providing customers with more professional services. We provide customized services, actively interact, and the equipment will be shipped after it is debugged.

Our team's slogan is: 100% high satisfaction, turning plastic into gold

Guangzhou Putong adopts the business model of "product end + high-function film + customized service". Based on the product end, it transforms the experimental equipment at the experimental end into process trial equipment at the product end and the market end. The high-function films studied by the equipment are widely used in electromagnetics, optics, acoustics and other fields. It echoes the national industrial development direction of new materials, new energy and environmental protection.

Guangzhou Putong puts meeting customer needs first and is willing to be a 24-hour supplier to customers. When providing customers with customized experiments and test equipment, it will do a good job in technical docking and pre-sales experimental testing services. Guangzhou Putong has set up several on-site process departments to provide customers with pre-sales experimental testing services, delivery and adjustment services, customer on-site adjustment services and 48-hour response after-sales services to ensure the smooth progress of customers' scientific research work.